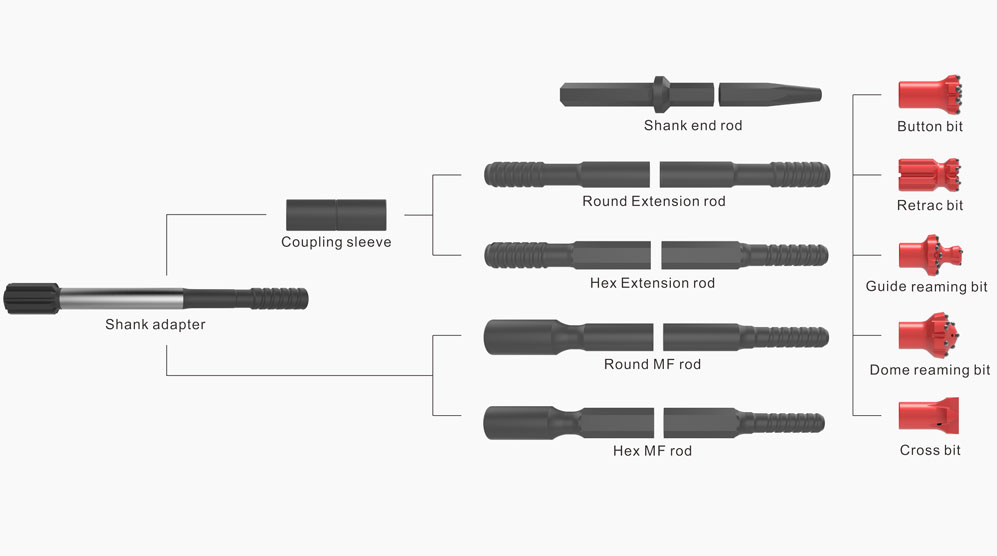

Top hammer drilling tools is a kind of rock tool consumables widely used in top hammer drilling applications, such as open-pit mining, quarrying, underground mining, rock bolting, tunneling, and production drilling. The top hammer rock drilling tools include four parts: Drill bit, Drill rod, Shank Adapter, and Coupling Sleeve.

Litian is a professional manufacturer of high-quality top hammer rock drilling tools with optimal drilling hole quality, high stability, and long service life. The top hammer tools are designed and produced to transmit high-frequency impact energy into the rock and minimize energy loss to improve the rock breaking rate, penetration rate, and productivity.

Top Hammer Rock Drilling Tool | ||

Material | Tungsten Carbide, Structural Alloy Steel | |

Thread | R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35, TR35, etc. | |

Bit Type | Standard button bit, Retrac button bit, Reaming bit, Tapered button bit | |

Skirt Design | Standard type, Retrac type, Straightrac type | |

Face Design | Flat face, Drop center face, Uni-face, Reaming type, Cross type face | |

Button Shape | Spherical buttons, Ballistic buttons, Conical buttons, Composite buttons | |

Head Diameter | 28mm~152mm | |

Material | Structural Alloy Steel | |

Thread | R22, R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35, TR35, EL60, EL68, etc. | |

Rod Type | Extension rod, Drifter rod, MF rod, MF Drifter rod, Guide tube, Drill Tube | |

Body Type | Round rod, Hexagonal rod | |

Diameter | 20mm~87mm | |

Length | 260mm~6400mm | |

Material | Structural Alloy Steel | |

Applicable rock drill | Atlas Copco, Sandvik, Tamrock, Furukawa, Ingersoll-Rand, Montabert, Boart LongYear, etc. | |

Thread | R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, SR28, SR35, TR35, EL60, EL68, etc. | |

Shank Type | Male threaded shank adapter, Female threaded shank adapter | |

Diameter | 32mm~90mm | |

Length | 370mm~1200mm | |

Material | Structural Alloy Steel | |

Thread | R32, R35, R38, T38, T45, T51, etc. | |

Coupling Type | Semi bridge Couplings, Full bridge Couplings, Crossover Couplings | |

Diameter | 44~72mm | |

Length | 150mm~255mm | |

Litian provides standard and heavy-duty series top hammer drilling rig tools, suitable for drilling in soft rock, medium-hard rock, hard rock, and various complex mixed rock working conditions. The drill bit, drill rod, coupling sleeve, and shank adapter are connected by their threads to form a rock drill string. The commonly used thread forms include rope thread (R25, R28, R32, R35, R38, SR28, SR35) and trapezoidal thread (T38, T45, T51, ST58, ST68, GT60).

In the top hammer drilling tool manufacturing, we have world-class production technology, advanced production equipment, and experienced production technical staff. We have been working closely with our customers to conduct extensive on-site tests on various types of rocks and working conditions. Based on the feedback, we continue to improve and develop in various areas such as raw materials, heat treatment, design and manufacturing processes.

In terms of product consultation and rock tool services, we can select the most suitable rock drill tools and drilling construction schemes according to the user's construction conditions, rock type, mineral conditions and drilling equipment, so as to help users improve drilling efficiency, reduce drilling costs, and achieve better comprehensive benefits and higher labour productivity.

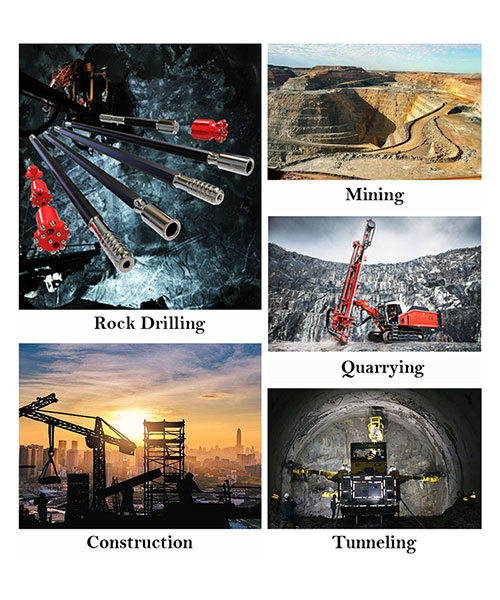

In terms of industry reputation, our top hammer drill tools have a good industry reputation in mining, tunnelling, quarrying, roads or construction due to their excellent wear resistance, roughening resistance and stability. Compared with many world-class brands of drilling tools, our rock drill tools are not inferior. In some field comparison tests, the use efficiency of our many products even exceeds that of world-class brands and has been highly recognized by customers.

Rock drilling tools are widely used in various industries, such as mining, tunnelling, and construction. These tools are specifically designed to drill through hard rock surfaces, and are essential for mining minerals, digging tunnels, and building roads or foundations.

Our drilling rig tools and mining machine parts are suitable for top hammer long hole drill rigs, rock support drill rigs, cable-bolting rigs, underground drill rigs, tunneling jumbos, narrow vein drill rigs, development drill rigs, surface top hammer drill rigs, dimensional stone drill rigs, and all other drilling rigs that use the way of top hammer drilling.

Litian top hammer rock drilling tool needs to be installed with the hydraulic rock drill on the rock drilling equipment for rock drilling. The rock drill works according to the principle of impact crushing. When the rock drill is working, the piston makes a high-frequency reciprocating motion, continuously hitting the shank adapter to produce impact energy, which is then transmitted to the drill rod, drill bit, and rock to achieve rock breaking.

①Raw material and technology

High-quality raw materials and advanced processing technology can guarantee the overall drilling quality of the rock drill tools from the source and prolong its service life. Choose qualified rock drilling tools and rock drill accessories from large standardized manufacturers.

② Whether the rock drill tools assembly are concentric

When drilling rock, the shank adapter, the drill rod, and the couplings should be in concentricity. The misalignment of the three will cause bending and deformation of the top hammer drill tools, resulting in stress, resulting in the joint can not cooperate effectively, and causing looseness.

③ Improper use of rock drill tools

When connecting the top hammer rock drill tools, it is easy to damage the rock drill tools if there are mud and sand on the thread, or if there is no lubricating oil at the threaded connection. The combination using of the used drilling rig tool and the new drilling rig tool will shorten the service life of the drilling tool. In addition, the empty beating of rock drill tools should be avoided as far as possible.

④ Propulsion pressure and impact pressure

The propulsion pressure and impact pressure should be set within the rated pressure range.

If the propulsion pressure is too low, it will reduce the drilling penetration efficiency, cause the drilling tool assembly to loosen, and the transmitted energy will be lost, which will cause great stress and cause the instantaneous contact and separation of the contact and joint end faces. If the pressure is too high, the rotation speed of the drill bit is low, there is a danger of sticking, and the bending stress of the drill rod increases.

Improper adjustment of the impact pressure will directly affect the rotation speed and drilling efficiency, and will also affect the life of the drilling tool.

⑤ Rotation speed and rotation pressure.

The rotation speed should match the drill bit diameter and the impact frequency of the top hammer drill tool. The cemented carbide of the drill bit has to be rotated at an appropriate angle after each impact, so that new rocks are broken each time.

The normal rotary pressure can provide proper anti-sticking protection for the drill rod. The increment of rotary pressure is the key factor to maintain the tightness of the rock drill tools. if the tightness is not enough, it often causes heating of the joint, peeling off of the thread surface, early wear and even fracture of the thread.